Case Study #1

10,000 sq ft Startup Warehouse

National Distribution Center in SW Ontario

Lean Kaizen Project

Results

Highlights:

Complete Warehouse transformation from what the company described as,

“A Complete Mess” to “A Well Oiled Machine” in only 2 Months12 Successful Lean Kaizen Improvements Completed in only 2 months

780% ROI at Today’s Kaizen Hero Consulting Rates

$635,000 Net Profits per year from Improvements

$2,000,000 of Product Inventory 100% Audited for Quality, Quantity & SKU Accuracy

10% Increase in New Business Sales

Additional Benefits

Project Completed in 6 weeks, 2x Faster than Estimated by Owners

600% Increase in Order Pick Speed from Well-Organized Inventory

100% Warehouse Inventory Accuracy with Daily Cycle Counts

100% Accurate Order Completion

99% Reduction in Back orders & Lost Opportunities

99% Increase of Same Day Order Completion

92% Inventory Quantity Accuracy Improvement

75% Less Customer Service Issues

65% Accuracy Improvement of Physical vs WMS Inventory

5S & Daily Inventory Cycle Counts Implemented

Significant Increase in Teamwork, Morale & Cooperation

Problematic & Expensive Low ROI Machinery Removed

Business Saved from Sales/Closure

“>

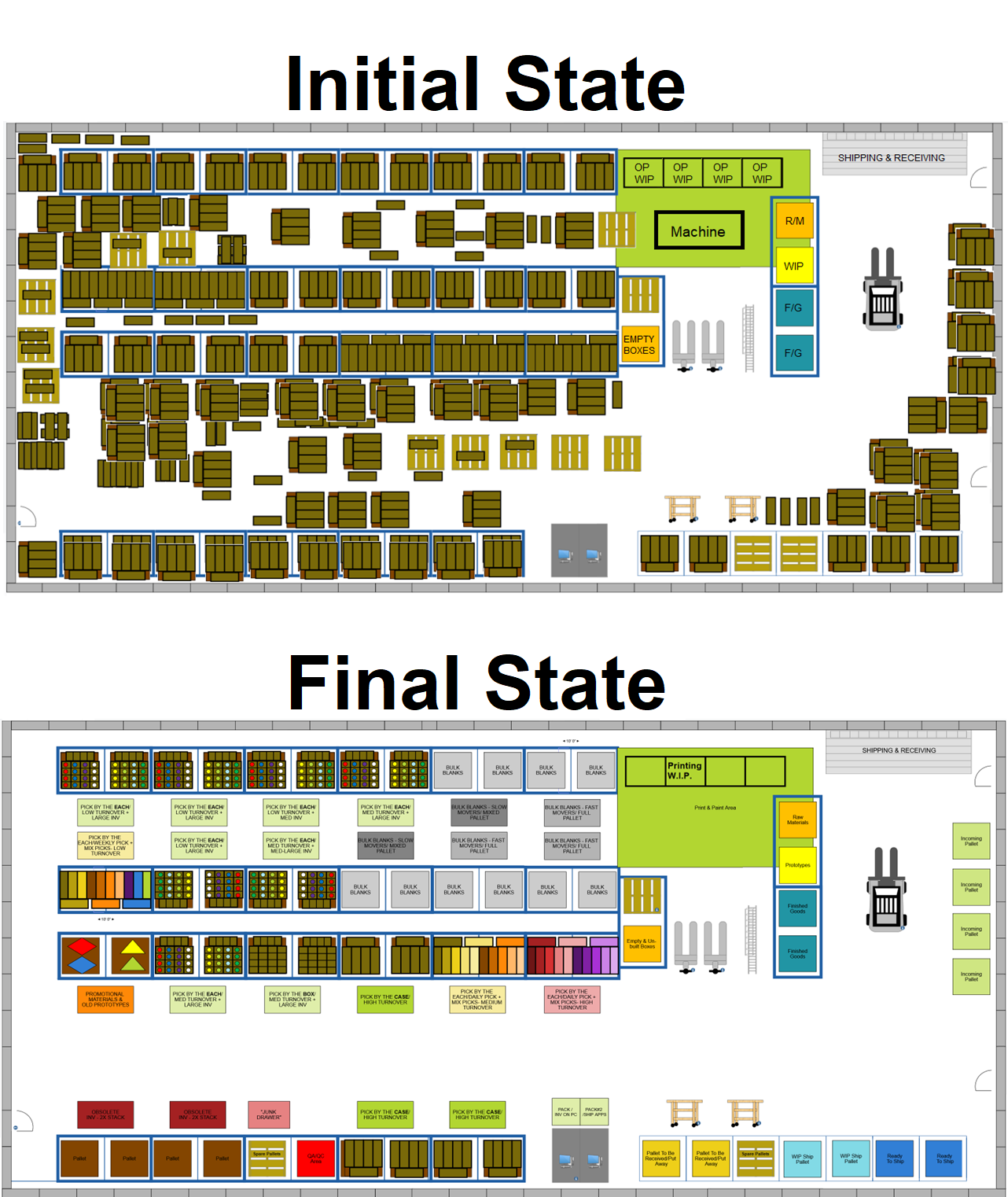

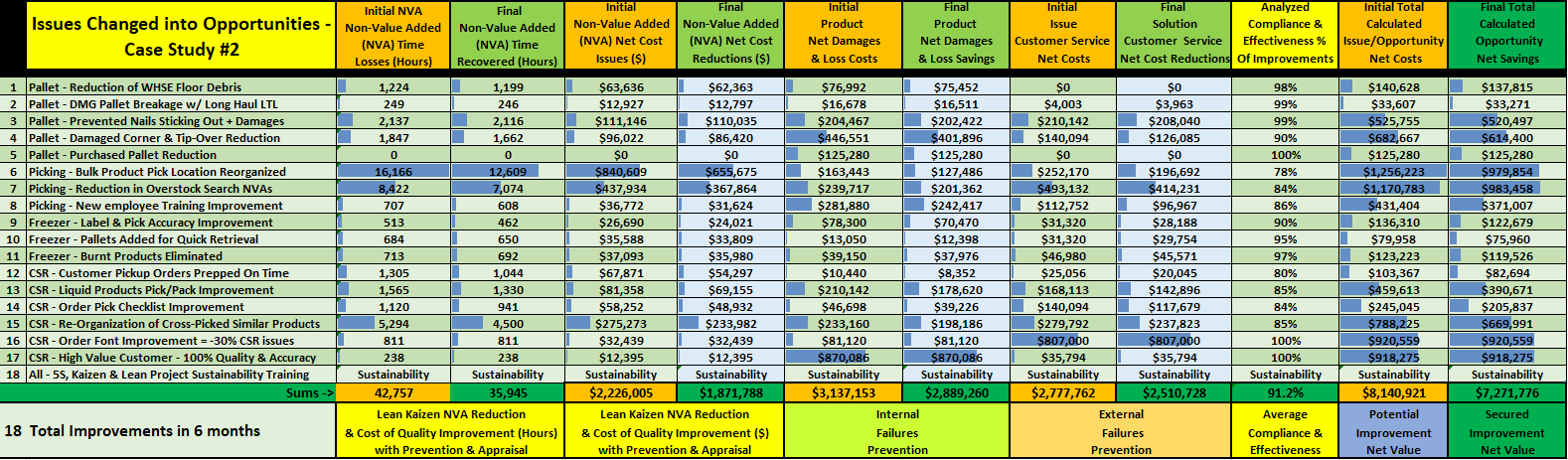

Case Study #2

National Distribution Center in SW Ontario

40,000 sq ft Food & Non-Food

Lean Kaizen Project

Results

Highlights:

18 Successful Low-Cost, High ROI, Lean Kaizen Improvements Completed in only 6 Months

896% ROI at Today’s Kaizen Hero Consulting Rates

$11,000,000 Total Yearly Increase in Net Profits

$7,200,000 Net Profits per year from Improvements

$3,800,000 in New Business Sales

30% Increased Company Growth (From Initial 3%)

Distribution Center Doubled in Size to 80,000 sq ft.

New Material Handling Equipment (MHE) Purchased

Additional Benefits

36,000 Hours in Non-Value Added Operations time Eliminated

$14,000 Increased Yearly Bonuses for each of the 100 Employees

88% Reduction in Overtime

81% Reduction in Damages/Lost Inventory, Pick & Pack Errors, Re-Shipped Products and Return to Stock

55% Reduction in Customer Service Issues

Significant Increase in Teamwork, Morale and Cooperation

Lean Kaizen Training Supported and Sustained all Improvements

New Employees Hired & Trained in Lean Kaizen Concepts

Business Saved from Sales/Closure

“>